FIKI Wiki

What You Need To Know About Icing Conditions and Systems

Source: www.faa.gov/news/safety_briefing, By James Williams

After studiously avoiding ice, you finally have access to an airplane whose specs include FIKI — approval for Flight Into Known Icing conditions. Before you launch into the winter skies with abandon, though, you first need to abandon the idea that FIKI offers a completely free pass. FIKI or no FIKI, as in any light part 23 aircraft, the safest

and most complete strategy is to simply avoid icing conditions. Good as they can be, today’s technology solutions still have limitations and ice can compromise or overwhelm even the best of them. That’s why it’s important to know what FIKI can and cannot do for you, which we’ll cover in this article.

Anti-Ice vs. Deice

First things first. The terms “anti-ice” and “deice” are sometimes confused, especially since an aircraft might be equipped with both. Here’s the difference. Anti-icing systems are designed to prevent ice from accumulating on protected surfaces or components. Deicing systems are designed to remove ice after it forms. Both systems have advantages and limitations in terms of performance, as well as in terms of installation and operation and some can even be used for both functions. Regardless of whether a system is used in an anti-ice or deice capacity, it’s useful to remember that there are basically three ways to deal with ice: heat it, treat it, or change it.

Heat It

The ice treatment solution you are most likely to see on airliners is leading edge heat. In turbine powered aircraft, this function is accomplished by directing bleed air from the engines to the leading edge of the wings, thus making them too warm for ice to form. While the “plumbing” of the ducts from the engines to all the protected surfaces might

be complicated (which makes it a less practical installation on GA aircraft), the relatively “free” heating source makes up for it. The very effective bleed air approach allows most airliners to tolerate far worse conditions than most GA aircraft.

Some GA aircraft do benefit from surface heating provided by electric heating elements. Elements like these are already used in applications such as pitot heat. The problems with broader use arise from the significant draw that electric heating elements place on the aircraft’s electrical system. In such cases — and usually for FIKI use — certification sometimes requires a separate dedicated alternator to handle the ice-related electrical load.

Change It

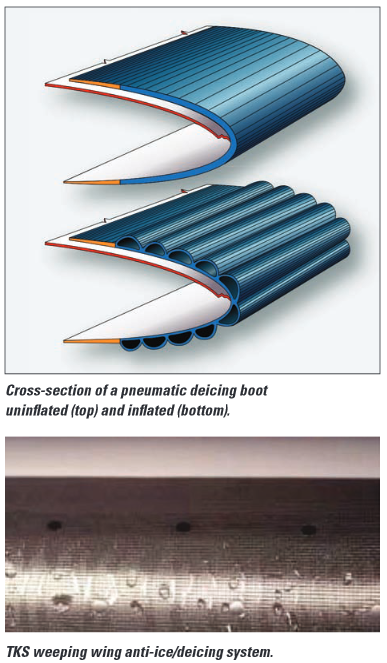

The second way of handling ice is to break it off — literally. Since you can’t exactly crawl out on the wing with an ice scraper (much less ask your passengers to do it), the technological solution is to use pneumatic boots to change the shape of the wing’s leading edge. Boots are a great way to remove ice from protected surface, but they are strictly a deicing solution since they don’t prevent ice formation.

Regardless of the mental picture conjured by the term, a de-icing boot consists of a series of narrow strips that run along the leading edge of the wing, or any other protected surface, and extend far enough back that ice is unlikely to accumulate. Because they require lots of high pressure air to inflate them, boots are usually reserved for select turbine or turbocharged aircraft. As long as the high-pressure air is available, though, boots have an essentially unlimited operating endurance, as they don’t put a massive load on the electrical system.

Before we move on, let me clear up a long-held misconception about “ice bridging.” For many years, the common practice for operating with boots was to wait for a specified amount of ice to accumulate before cycling the boots. The idea was to prevent ice from forming around the boots in their expanded form, thus rendering them useless in breaking off additional ice. After much NASA research, though, new guidance states that the best strategy is to activate the boots as soon as icing conditions are encountered. According to the NTSB, “Leading-edge deice boots should be activated as soon as icing is encountered, unless, the aircraft flight manual or pilot’s operating handbook specifically

directs not to activate them.”

Treat It

For GA aircraft, one of the most accessible means of deicing (which, depending on the application, can also be an anti-icing solution) is through “weeping wing” technology. In this approach, special panels are installed at the leading edge of all protected services. These panels extrude, or “weep,” a mixture of fluid that can provide both deicing and

anti-icing protection. An advantage of this approach is that the rearward flow of the fluid over the wing surface protects a broader surface area.

The weeping wing approach does not create a large electrical draw or require heated air. However, weeping wing solutions have two drawbacks. One is the added weight of the tank, pumps, plumbing, panels — and of course, the fluid itself. A second is the very definite operating time limit. The system can only function so long as there is fluid, which means that icing protection is exhausted as soon as the tank is empty. The size of the tank varies depending on installation and customer desires, but the operating time is usually in the range of 90 minutes to three hours, depending on flow rate.

The Wing’s Not the Only Thing

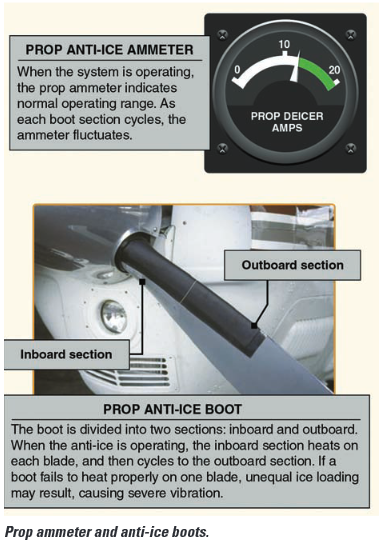

Bear in mind that in addition to the wings and stabilizers, other aircraft surfaces need to be protected. These usually include windshields, propellers, and possibly air intakes or sensor ports. This is usually where you get some technology mixing. A boot-equipped aircraft may have a heated windshield and alcohol-equipped props. Smaller items like sensor ports are usually covered by small heating elements similar to pitot heat. Another item is an ice detection system. Such systems are fairly elaborate in the airliner world, but sensors in GA aircraft can be as simple and as basic as a light that allows you to monitor the condition of a representative surface.

Houdini or FIKI

Even with — or maybe especially with — a FIKI capable aircraft, there is still a decision to make with respect to actually operating in icing conditions. With a non-FIKI airplane, it’s a clear no-go. With a FIKI capable aircraft, though, the decision requires a thorough understanding of systems — both technological systems and weather systems.

With respect to the technology, you need to be very clear on whether the aircraft is approved for FIKI and if so, under what conditions and limitations. In many circumstances, even approved systems will not allow prolonged flight in icing conditions. The best source for this information is the Pilot’s Operating Handbook (POH), which will include a supplement for the installed system(s). Unless the supplement clearly states that the aircraft is approved for flight into icing conditions, you do not have a FIKI capable

aircraft. In many cases, though, the POH supplement for non-FIKI equipment will clearly state that Flight into Icing Conditions is Prohibited.

Remember, too, that STC installation of weeping wing or boots does not carry FIKI approval in and of itself. An STC means only that installation of the item will not have a negative impact on aircraft systems or operation, but it does not indicate whether any benefit claimed by the manufacturer has been tested. Many of these systems are designed only to allow the pilot to escape unforeseen ice, and not for intentional flight into such conditions. And, especially with a limited ice escape system, know what the technology can and cannot do. For example, a FIKI-capable TKS™ system is likely to provide greater coverage, a larger tank, and redundant pumps as compared to the non FIKI system. Many escape systems also don’t provide windshield coverage. It’s also important to know that there can be a FIKI and a non-FIKI option for a lot of systems. Buyer beware!

Though a discussion of winter weather and icing is beyond the scope of this article, any decision with respect to flying in known icing conditions requires the pilot to have a detailed understanding of weather conditions and forecasts along the route of flight. Not even the stoutest of GA aircraft FIKI systems can withstand the onslaught of perils like freezing rain or supercooled drizzle drops. As in any kind of weather flying, knowing the fastest or safest way out of ice (or other hazardous conditions) is a critical part of the flight planning process.

One last thought for this FIKI WIFI survey: you can never know enough about weather, and you can never know too much about the systems you have to help you through it. Knowledge is the key to making the most of your technology and, if you’re fortunate enough to fly FIKI, to using it safely and well.

Learn More

AC-91074A Pilot Guide: Flight In Icing Conditions - http://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_91-74A.pdf

Ice Protection Systems Compliance Requirements (14 CFR 2 3.1419)- http://go.usa.gov/dEET

James Williams is FAA Safety Briefing’s associate editor and photo editor. He is also a pilot and ground instructor. |